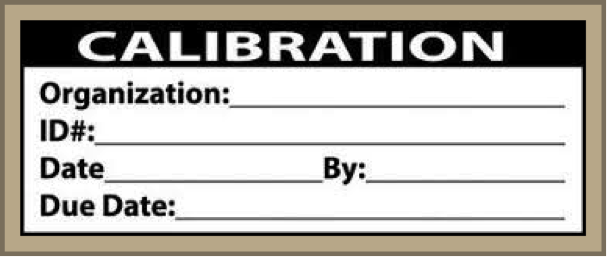

Components of a Calibration Certificate

Due Dates

Even though an instrument may have been supplied with a calibration certificate from the manufacturer, unless this certificate indicates its traceability, then it's not worth very much.

It is therefore important to have new equipment suitably calibrated at the time of purchase before putting them into use. This calibration will also form part of the commissioning or qualification of an instrument, and also gives useful evidence in a case for a warranty claim if an instrument is found to be out of specification.

How often should the instrument be recalibrated? The ISO standard 17025 firmly puts this decision into the hands of the user. A typical calibration certificate may carry a statement that a recalibration period must be chosen that will ensure that the accuracy of the instrument stays within predetermined limits, but again those limits are to be determined by the user.

Generally speaking though, recalibration should be performed when you no longer have confidence in the measurements made by the instruments, or can no longer prove traceability of the measurements.